This rule is essential in order to maintain the electrical continuity of the effective ground-fault current path required for metallic cables and raceways. However, to use them with metallic cables and raceways, an internal bonding means must be provided between all metal parts. These rules can seem arbitrary, but there really is logic behind them.įor example, nonmetallic boxes can be used with nonmetallic cables and raceways. With more than 20 common recessed can light cutout sizes needed the sizes available are seldom going to work.Article 314 contains installation requirements for outlet and pull boxes, junction boxes, conduit bodies, and handhole enclosures. Each size of carbide grit hole saw costs between $45 and $80 depending upon the brand and the hole saw only works for one size hole. There good reasons why this is often not the case. In theory it would be simpler to use a continuous edge tungsten carbide rim grit hole saw and cut through all three layers. For chicken wire it is best to use diagonal cutting pliers (dikes) or snips to cut the wire lath. For wood lath a fine tooth bi-metal reciprocating saw blade usually works the best. For standard metal lath a carbide grit reciprocating saw blade works very well. The best tool for cutting the lath depends upon the material used.

#PLASTER RING RECESSED LIGHTING CRACK#

With the circular scoring motion of the tungsten carbide cutting blades the two layers of the plaster are not likely to separate and cause a crack in the ceiling (which can be very expensive to repair).

#PLASTER RING RECESSED LIGHTING PRO#

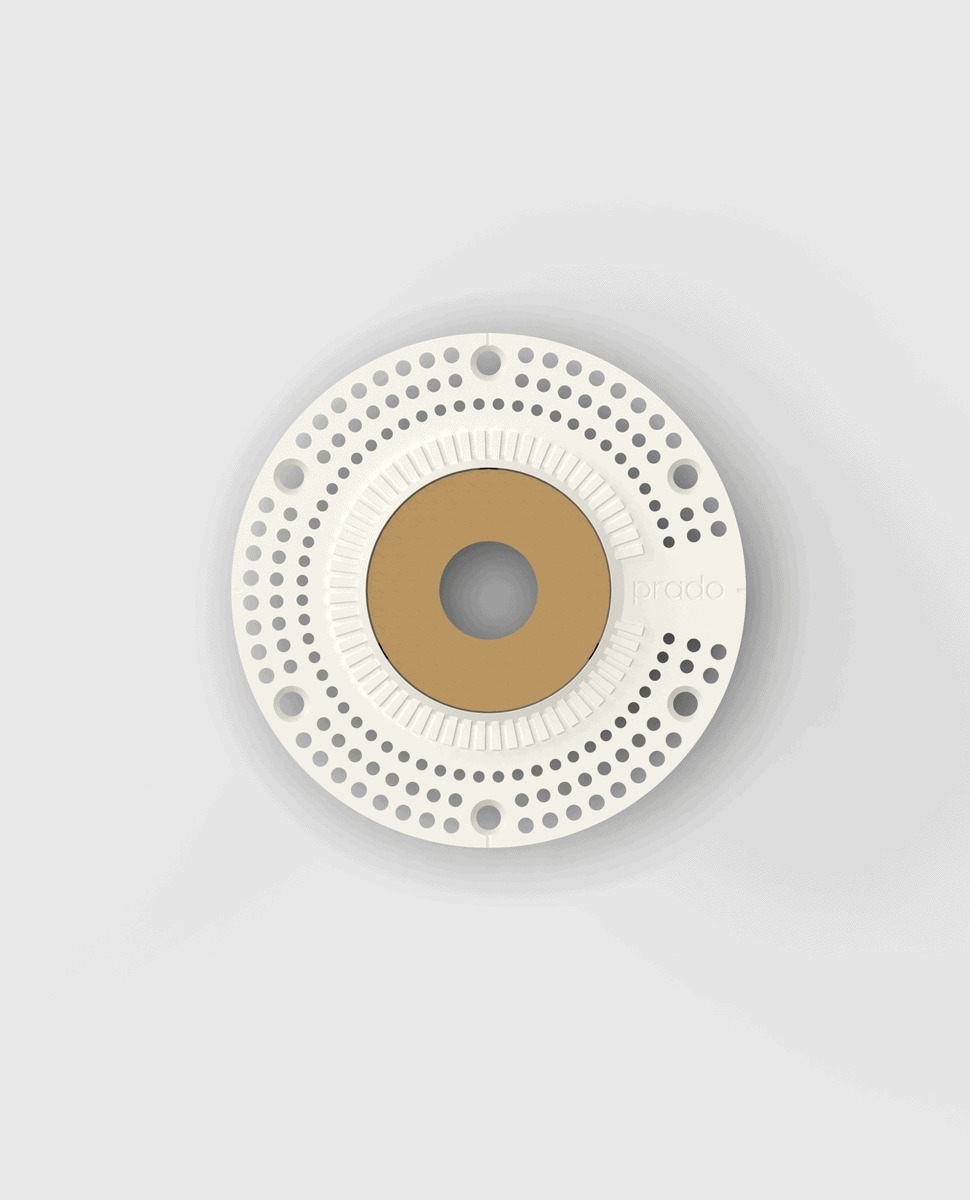

The Hole Pro adjustable hole cutters make a clean straight cutout hole in the plaster for the can light or ceiling speaker and with the straight edge the grill or trim rings will sit flush against the surface of the ceiling. Second cut the lath using the hole in the plaster as a guide. First cut the plaster and remove the plug. We recommend treating the plaster ceiling hole cutting operation as a two stage process. In many cases the nails that originally held the pieces of lath in place have largely disappeared from corrosion over the years. In prior years the lath could be metal, chicken wire, or wood. After 1950 most plaster ceilings have a metal lath. Plaster ceilings have been done in different ways in different parts of the country and at different times. There are many times when one or more holes need to be made in a plaster ceiling, whether for recessed light cans, audio speakers, a heating or air conditioning duct, or to add a ceiling fan.

Although we don't have any holes to cut right now, we're trying to think of excuses to buy one of these (Hole Pro)! Thank you to Hole Pro for letting us reprint their article. Be sure to visit their web site for more of their product information. We think you will find their article very helpful-particularly if you have a plaster ceiling (be it new or old). Often, mistakes are made-some of which are very difficult to correct for. We get a lot of customers with questions in regards to cutting the holes for recessed lighting. Note: this article is reprinted in its entirety with permission from the blog of the nice folks at Hole Pro.

0 kommentar(er)

0 kommentar(er)